The exeprt goes here…..

Leveraging Large Inventory for OEM Success: A Meister International Strategy

June 20, 2025

In an industry where the supply chain is king, Power Grid Components Inc.’s subsidiary Meister has distinguished itself through impressive inventory management. With over two thousand porcelain, cycloaliphatic, and polyester insulators and bushings on hand and ready for shipment. This not only ensures they are always supported, but also provides a vital competitive edge.

In Stock and Ready for Immediate Shipment

The extra edge that has placed Meister in this strategic position is a stockpile of inventory that they can dispatch within one day. The significant inventory is not merely a figure—it is a source of hope to OEMs, Utilities, and Repair Companies struggling with production hitches occasioned by shoddy supply chain management. While competitors make it take as long as 18 weeks to prepare the orders for shipping, Meister’s offer to ship the orders immediately helps firms stay on track and avoid idle time.

Responsive Customer Service

Another key factor that has contributed to the success of Meister is the great customer service provided by the company. It processes as many calls as requested in a single day and is lauded for its ability to complete calls in a relatively short time. Our measure of customer service is minutes, not hours. This is welcome, especially in an industry where time is money; this gives the OEMs assurance they have a good partner who is but an email or phone call away. The kind of responsiveness shown is an example of the kind of customer care that Meister has for its clients, and it is an important asset in the long-term business with the customers.

Quality and Durability

Where speed and volume are paramount, cost is not a factor at Meister. Every insulator in their large stock is built to precise specifications to ensure they meet and exceed industrial and utility standards.

Cross-Selling Capabilities

Beyond just supplying insulators, Meister leverages its position in the fold of Power Grid Components Inc. to raise its cross-selling capabilities. This competitive advantage allows Meister to sell its own products and those of its sister companies like Newell, ITEC, and Royal. When Meister gets an order from OEM customers, the customers have the benefit of being in a position to procure a broader range of complementary products that can be shipped together. This facilitates easier procurement for customers and drives innovation and efficiency in customers’ projects by making a wider range of high-quality components from established sources within the same corporate family available.

Competitive Advantage

Meister’s unparalleled inventory levels and rapid response are in stark contrast to the lengthy wait times and minimal communication of most of its competitors. This has allowed Meister to secure and grow customer business and become an OEM market partner of preference. Shipping high-quality products promptly and responding to customer calls quickly have made Meister one of the industry’s top players.

Partner with Meister: Your Gateway to Enhanced OEM Efficiency

For OEMs looking to optimize their operations and maximize their production efficiency, dealing with Meister is a proven path to success. With our vast inventory, excellent customer service, and unyielding commitment to quality, we are prepared to serve your projects and make your goals attainable in no time. Contact Meister today to discover how our inventory solutions can transform your supply chain problems into competitive advantages. Let’s construct success together because at Meister, we’re ready when you are!

Grid Chronicles

Same Day Shipping: The Competitive Edge for Electrical Insulators Distribution

The ability to deliver components on demand is not just a convenience — it’s a game changer. Meister International...

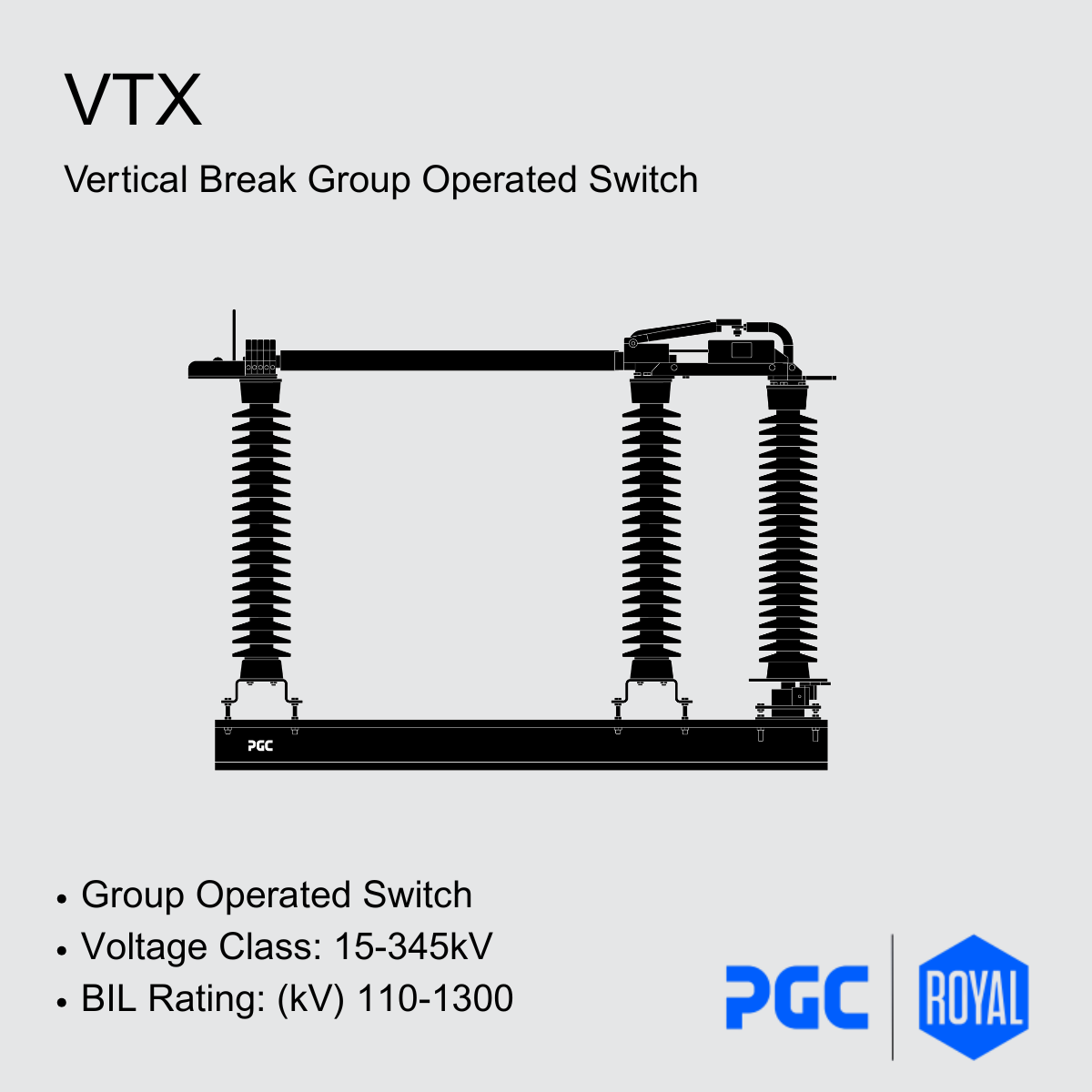

Read morePower Up with Innovation: Royal’s VTX Switches

Royal has consistently prioritized the longevity of its products, and the VTX switch is no exception. By enhancing operational smoothness and minimizing heat at connection...

Read moreMeeting Urgent Needs: Newell’s Commitment to Short Lead Times

In the fast-paced world of industrial and utility applications, time is of the essence. Whether it’s an unexpected outage or a tight project...

Read more