Where station post insulators are concerned, choosing to utilize porcelain or composite materials is critical to maintaining long-term stability and performance in the power transmission system. Though both have varying advantages, your decision must be based on the specific needs of your project, external environmental conditions, and long-term performance specifications. This blog will discuss the primary differences between porcelain and composite station post insulators to allow you to make an informed purchase decision for your next order.

Station Post Insulators: Porcelain vs Composite

April 2, 2025

Where station post insulators are concerned, choosing to utilize porcelain or composite materials is critical to maintaining long-term stability and performance in the power transmission system. Though both have varying advantages, your decision must be based on the specific needs of your project, external environmental conditions, and long-term performance specifications. This blog will discuss the primary differences between porcelain and composite station post insulators to allow you to make an informed purchase decision for your next order.

Durability and Mechanical Strength

Porcelain

With over 50 years of manufacturing history, Newell’s porcelain station post insulators have superior mechanical properties. Porcelain exhibits better endurance with high mechanical stress, torsion, and compression resistance and can be used for long-term application in both non-stacking (up to 161 kV) and stacking (230 to 765 kV) uses. Porcelain mechanical ratings include a cantilever strength that is a function of the insulator size.

Composite

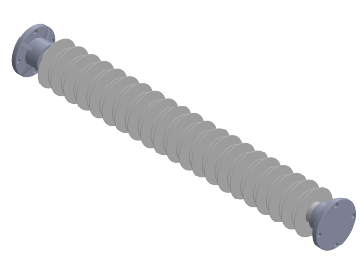

On the other hand, composite insulators, made from fiberglass rods with bonded silicone rubber coverings, also exhibit excellent mechanical strength. Newell’s composite insulators, for example, may have mechanical ratings equal to, if not superior to, porcelain, and their cantilever strength will be a function of the insulator’s size. Composite materials are flexible and can flex slightly under mechanical loads without breaking, which is beneficial when subjected to vibration or dynamic loading.

Environmental Performance

Porcelain

Porcelain station post insulators offer very high resistance to environmental deterioration. Newell also offers porcelain insulators with an NPRTV® coating, which provides extra protection against industrial contamination and salt spray. The coating further eliminates the requirement for frequent washing and resists power loss due to contamination. Uncoated porcelain, however, may retain contamination more in highly polluted environments, leading to a diminution of performance over time.

Composite

The structure of composite insulators makes them naturally resistant to environmental damage. The silicone rubber housings on these insulators create water-resistant surfaces that protect against the buildup of contaminants. Composite insulators work best in areas with high levels of contamination, including coastal areas and industrial zones. Such insulators reduce the probability of flashover incidents triggered by environmental contaminants.

Electrical Performance

Porcelain

According to ANSI, porcelain insulators exhibit better electrical performance, with impulse-withstand voltages ranging from 95 kV to 2050 kV. They are reliable insulators under high-voltage conditions; hence, porcelain insulators are a safe choice for most utility applications. The longevity of porcelain insulators extends beyond decades because they maintain their electrical properties throughout time.

Composite

According to ANSI, composite insulators are also reliable electrically, with a maximum impulse withstand voltage of 1470 kV. They perform exceptionally well where flashover of environmental contaminants is a problem, as the hydrophobic nature of the silicone rubber housing prevents electrical discharge in contaminated conditions.

Weight and Ease of Installation

Porcelain

Due to their great weight, porcelain insulators present significant burdens for both shipping activities and project installation. A porcelain insulator that works at 110 kV BIL exceeds 16 lbs. The weight invested to enhance strength creates installation challenges for limited access or when working at high elevations.

Composite

Composite insulators are considerably lighter and, therefore, easier to transport and install. A standard composite station post insulator for application with 110 kV BIL installations may weigh as little as 7 lbs, thus allowing quicker, cheaper installation. Composite insulators would be the natural choice, and installation cost and time must be minimized.

Cost and Availability

Porcelain

Porcelain insulators also cost less upfront. Newell’s porcelain insulators can be stocked from inventory with short lead times and rapid delivery, a valuable selling feature compared to the competition. However, the cost of maintaining clean and coated porcelain insulators in filthy surroundings does add up in the long run.

Composite

Even though composite insulators can cost more initially, they do not require more maintenance and survive longer under harsh conditions. Their ability to withstand contamination and need to be cleaned less often can translate to lower overall lifecycle costs in places with high industrial pollution.

Which Should You Choose?

Deciding between composite and porcelain station post insulators ultimately comes down to your project needs. If you want a tried-and-true, cost-effective solution with lower upfront costs, porcelain could be the best option, especially for less extreme environments. However, if you have high contamination or challenging installation conditions, composite insulators might have a better long-term value because they require less maintenance and weigh less.

Making the Right Choice for Your Project

When choosing between porcelain and composite station post insulators, you must weigh your project’s long-term benefits and personal needs. Newell’s extensive inventory of both options provides you with quality products with industry-leading shortest lead times, no matter the choice. Either option, the tried-and-tested dependability of porcelain or composites’ inherent flexibility, Newell possesses what it takes to provide your power transmission work with the best in either event.

Contact Newell today to discover our full range of insulators and why many contractors and utilities trust us with their mission-critical infrastructure projects.

Grid Chronicles

The Winter Performance of Glass Insulators: What You Need to Know

Winter can stress the strength and integrity of each component in an electrical system, especially insulators...

Read moreProtecting Electrical Systems in Coastal Regions During Winter Storm Season with Semi-Conductive Glaze Insulators

Winter storm season comes at a critical time for powering a reliable electrical grid...

Read moreUnderstanding Bushing Assemblies: Distinguishing Low and High Voltage Solutions

Bushing assemblies are critical components of the electrical system, functioning as key connectors that provide a vital link...

Read more