Wind-powered offshore electricity is becoming an essential source of renewable energy for millions of homes. However, transmitting this energy to the onshore grid presents a unique set of challenges due to the harsh marine environment. To overcome these hurdles, high-voltage insulators, specifically engineered for offshore conditions, play a critical role in ensuring reliable and uninterrupted energy transmission. These advanced solutions are helping to support and strengthen the next generation of offshore wind infrastructure.

How High-Voltage Insulators Ensure Reliable Power Transmission from Offshore Wind Farms

September 4, 2025

Wind-powered offshore electricity is becoming an essential source of renewable energy for millions of homes. However, transmitting this energy to the onshore grid presents a unique set of challenges due to the harsh marine environment. To overcome these hurdles, high-voltage insulators, specifically engineered for offshore conditions, play a critical role in ensuring reliable and uninterrupted energy transmission. These advanced solutions are helping to support and strengthen the next generation of offshore wind infrastructure.

Tackling Contaminated Environments with Advanced Materials

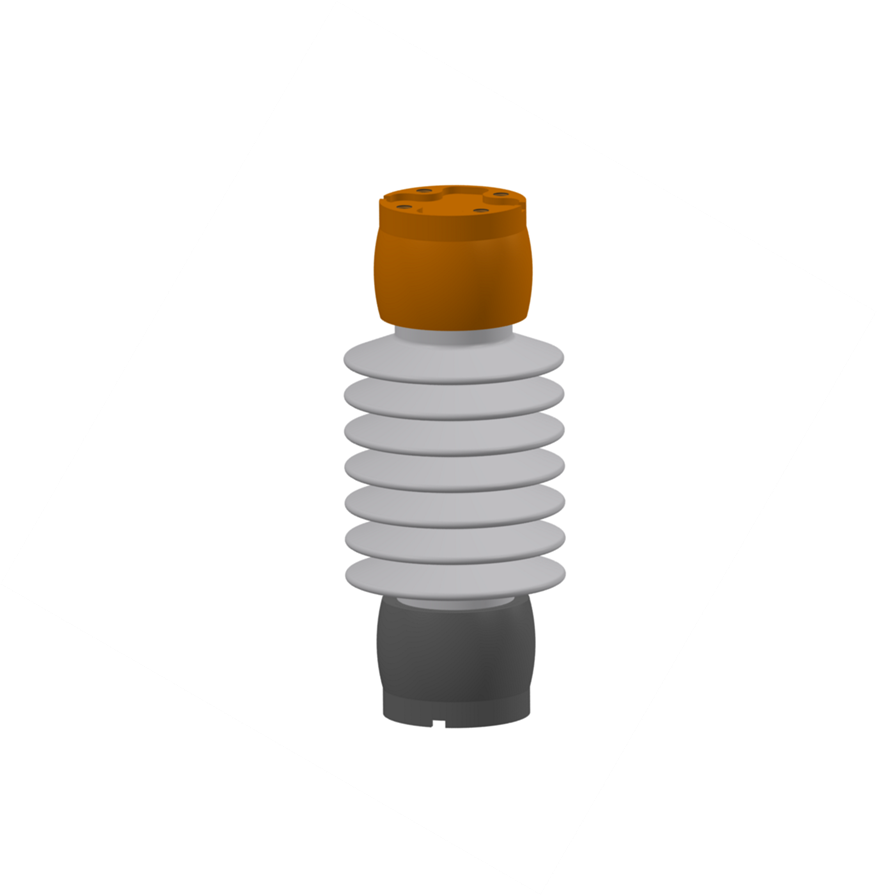

Adverse to the marine environment, power transmission equipment must contend with the internal limitations of salt fogs and sea mist, which can conduct high currents and lead to short-circuiting in normal insulators. Semi-conductive glaze insulators by Newell are specifically designed for such an environment. With the use of advanced dopants like those of tin and antimony, the glaze converts itself from an insulating to a semi-conductive property, thereby minimizing leakage currents of any kind and performing with operational stability. These insulators meet artificial pollution tests as defined by IEC and perform better than conventional insulators at salinities up to 224 kg/m³. High-voltage insulators protect against clean contamination failure for faultless operation at offshore wind farms.

Solid Core Construction to Counteract Adverse Weather

Harsh weather conditions, such as icing, snow bridging, or gusts, are the usual conditions offshore. Insulation material, therefore, used in such weather conditions needs to have superiority in resilience. All this has led to cutting-edge technology where Newell’s solid core construction eliminates all the limitations of hollow-core designs and offers unparalleled mechanical strength and reliability.

Built with durability in mind, these insulators are engineered to endure substantial mechanical stress while withstanding the corrosive effects of the offshore environment. This resilience translates to fewer maintenance demands and less unplanned downtime—key advantages for operators managing remote wind installations.

Enhanced Performance in High-Voltage Applications

High voltage transmission requires insulators that are capable of withstanding gargantuan electrical stresses without a compromise to either the safety or the efficiency of operations conducted. Newell insulators are tested to meet even the most demanding standards of ANSI, IEC, and IEEE specifications. Accordingly, for instance, semiconductive glaze systems undergo 100 percent leakage current testing, thereby ensuring ultimate performance when used at high voltages.

Maintaining the necessary level of capacitance and reducing resistive leakage enables efficient energy transfer occurring from the turbines to the onshore grid, and therefore reduces energy losses while delivering maximum output.

Short Lead Times to Enable Significant Infrastructure Projects

One of the best advantages that Newell offers is its commitment to holding a robust supply of high-voltage insulators in stock. Unlike its rivals, a hands-on stock indicates insulators are almost always available for shipment. For offshore wind farm developers, this equates to shorter program durations and lower incurred costs related to delays.

Newell’s quick response to the market assures that it is a dependable ally in this speed-of-light system of renewable power, whether utilities, contractors, or distributors are being supplied.

Proven Reliability Backed by Decades of Expertise

With years of experience, Newell’s semiconductive glaze technology has been demonstrated to be nearly flawless. These extensive years of experience, coupled with stringent quality control of insulators, ensure all insulators are being produced to the highest standards of reliability and endurance.

Newell’s insulators undergo performance testing under the most extreme conditions through ANSI/IEEE tests and artificial pollution testing. Consequently, they become a necessity in offshore wind farm power transmission.

A Commitment to American Manufacturing and Support

With an extensive network of warehouses across the U.S. and strategic international partnerships, Newell is well-positioned to meet the high-voltage insulator demands of its global customer base. Backed by a skilled and experienced team, the company is known for delivering industry-leading lead times and has become a trusted partner for renewable energy projects nationwide.

Its strong local presence also ensures full compliance with U.S. standards and enables fast, dependable customer service.

Partner with Newell for Offshore Wind Power Reliability

High-voltage insulators are not merely components but the structural framework of any serious offshore wind power transmission project. With the latest materials and innovative ideas in design, and with proven commitment to the highest quality and punctual deliveries, Newell’s insulators are the best of the best in the industry and the ideal choice. Whether you’re a utility manager, contractor, or procurement specialist, Newell offers comprehensive solutions essential to maintaining reliable power delivery.

Are you ready to take your renewable energy projects to a whole new level? Get in touch with Newell for more information about our high-voltage insulator solutions!

Grid Chronicles

Durability and Reliability: How Semi-Conductive Glaze Insulators Thrive in Freezing Temperatures

Insulator reliability and lifespan are critical for high-voltage power systems in freezing weather conditions....

Read moreThe Backbone of Substations: Understanding Station Post Insulators

When you think of the critical components of an electrical substation, transformers, circuit breakers, and switches might come to mind....

Read moreVizimax’s Global Footprint: Powering Reliable Electrical Grids Worldwide

Across more than 40 countries, utility and industrial customers depend on Vizimax’s advanced switching solutions and innovative control technologies to build....

Read more