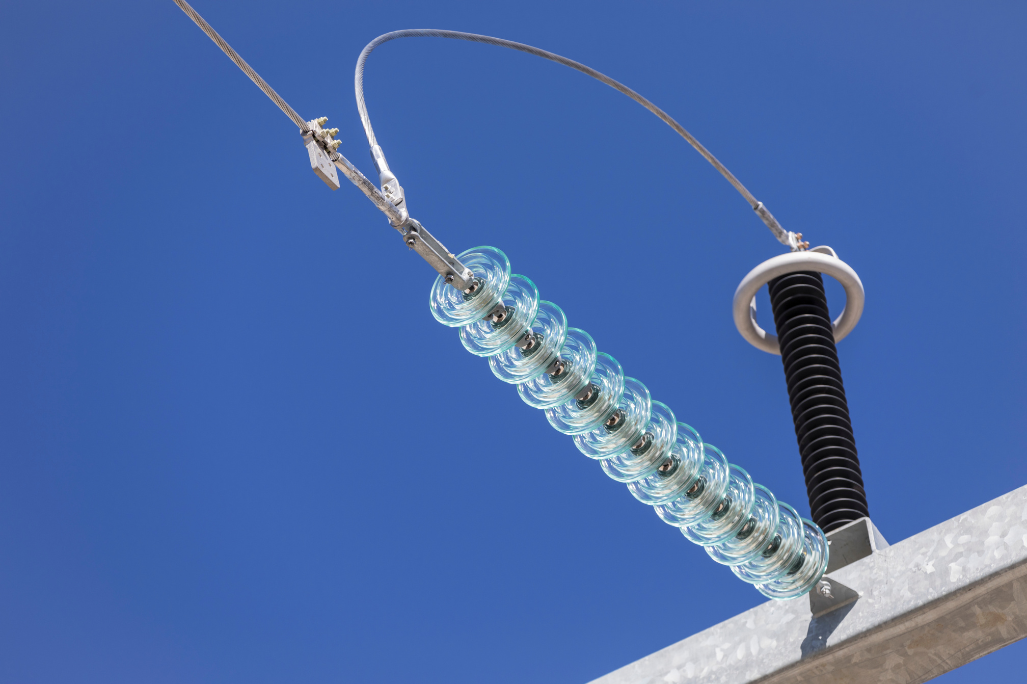

Winter storms bring more than just snow and ice—they pose a significant challenge to power transmission systems, especially in areas with contaminants. These areas, often plagued by salt spray, industrial pollution, or agricultural dust, are subjected to a greater risk of power outages because the conductive paths contaminants provide for electricity. Fortunately, Newell’s semi-conductive glaze insulators offer a revolutionary solution that can withstand such challenges. Learn how Newell’s technology can keep power flowing smoothly this winter.

Reducing Power Outages in Contaminated Areas During Winter: How Newell’s Insulators Can Help This Winter

January 27, 2026

Winter storms bring more than just snow and ice—they pose a significant challenge to power transmission systems, especially in areas with contaminants. These areas, often plagued by salt spray, industrial pollution, or agricultural dust, are subjected to a greater risk of power outages because the conductive paths contaminants provide for electricity. Fortunately, Newell’s semi-conductive glaze insulators offer a revolutionary solution that can withstand such challenges. Learn how Newell’s technology can keep power flowing smoothly this winter.

The Science Behind Semi-Conductive Glaze Insulators

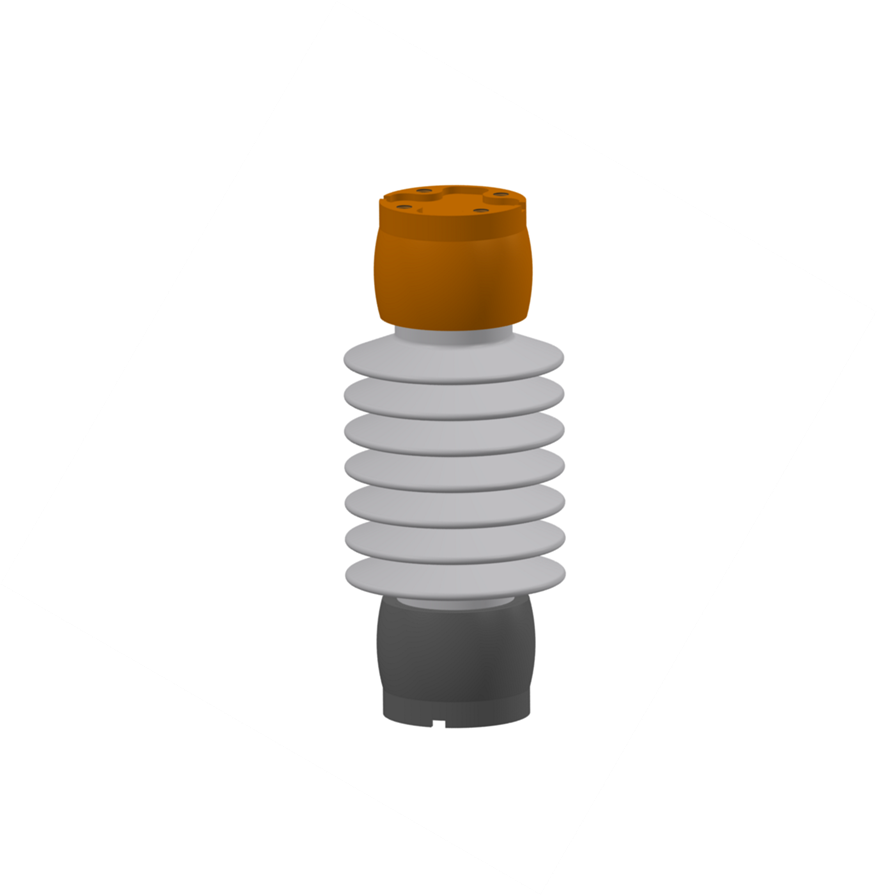

Newell’s semi-conductive glaze insulators are designed for use in contaminated conditions. The glaze is constructed using materials like tin oxide and antimony oxide, which provide it with a high level of resistance to the harmful effects of contaminants. The glaze is special in that it can conduct sufficient electricity to help reduce surface accumulation, thereby reducing flashovers caused by pollutants.

Whether dealing with seashore salt in coastal areas or coal dust in areas of heavy industry, Newell’s insulators perform well under adverse conditions. The company’s creative design also addresses issues such as snow bridging and icing, which are common problems during winter storms that can disrupt transmission lines.

Exceptional Durability in Extreme Conditions

Insulators for a polluted environment require immunity to environmental and electrical stresses. Newell’s semi-conductive glaze insulators have been subjected to rigorous tests under ANSI, IEC, and IEEE standards, ensuring reliability and longevity.

For example:

- Artificial Pollution Testing: These insulators were subjected to comparative testing under salt concentration levels as high as 224 kg/m³ and were found to be superior to conventional insulating glaze and silicon-coated insulators.

- 100% Solid Construction: Unlike hollow-core insulators, the solid core of Newell’s design withstands mechanical forces, thus ensuring performance under the harshest environmental conditions.

Due to such durability, the number of outages and the maintenance costs associated with them have decreased, which is critical during winter storms.

Designed for Contaminated Areas

The semi-conductive glaze insulator developed by Newell is applied in cases where contaminants constantly pose a challenge. Typical applications are as follows:

- On the Coast: Where it withstands salt fog and mist that corrode the traditional insulators.

- In Industrial Areas: Where it resists coal dust, chemical pollutants, and cooling tower mist in places like power plants.

- In Agriculture: Where it endures crop dust and fertilizers that create a conductive pathway for electricity.

All of these characteristics make Newell’s insulators the preferred option for transmission lines and substations in high-risk zones.

Short Lead Times for Critical Winter Needs

When winter storms hit, rapid access to high-quality equipment is crucial. Unlike the competition, Newell guarantees a steady inventory of semi-conductive glaze insulators, providing some of the industry’s shortest lead times. As either a purchasing manager or sourcing expert, this availability is reassuring and reduces downtime.

Newell’s geographically dispersed warehouses across the U.S. provide speedy shipment, ensuring the power utilities receive a continued, uninterrupted flow.

Proven Field Performance and Custom Solutions

Newell’s semi-conductive glaze insulators are field tested and display proven performance. Newell provides not only standard designs but also customizable designs to meet very tight needs, such as:

- Extra leakage distance and extra high-strength configurations

- The option for horizontal or vertical installation

- Mounting configurations addressing special environmental challenges

This flexibility guarantees that utilities receive the suitable solution required to ensure the dependable operation of their systems.

Supporting the Grid with Reliable Insulators

Winter storms really put our electrical infrastructure to the test, and Newell’s insulators stand up beautifully to this challenge. By countering failures due to contamination, these products also prevent outages, enhancing this system’s reliability and sparing communities from severe power interruptions.

Keep Your Power Flowing This Winter

With a track record for innovation and reliability, Newell’s semi-conductive glaze insulators are the ideal answer to guarantee power transmission even in polluted and challenging environments. Let neither pollution nor winter storms cause disruption to your grid.

Contact Newell today to learn more about how our advanced insulators can protect your system and ensure uninterrupted service this winter season.

Grid Chronicles

The Winter Performance of Glass Insulators: What You Need to Know

Winter can stress the strength and integrity of each component in an electrical system, especially insulators...

Read moreProtecting Electrical Systems in Coastal Regions During Winter Storm Season with Semi-Conductive Glaze Insulators

Winter storm season comes at a critical time for powering a reliable electrical grid...

Read moreUnderstanding Bushing Assemblies: Distinguishing Low and High Voltage Solutions

Bushing assemblies are critical components of the electrical system, functioning as key connectors that provide a vital link...

Read more

Vizimax engineers in Guatemala at a training session with our partners, Inde Guatemala and Multioperaciones, in 2018.

Vizimax engineers in Guatemala at a training session with our partners, Inde Guatemala and Multioperaciones, in 2018. Vizimax and Scope T&M team at Elecrama 2016 event in Bangalore, India.

Vizimax and Scope T&M team at Elecrama 2016 event in Bangalore, India.